LARGE SIZE HYDRAULIC EXCAVATORS

Technical Specification

| Diesel Drive (Make) Tier 2 | Komatsu

SDA12V159E-2

| |

| Output at 1800 rpm | kW HP | 940 1,260 |

| Electric Drive Output | kW | 900 |

| Main Pumps Delivery (total) | ltr/min | 3 x (2 x 455) = 2,730 |

| Swing Pump(s) Delivery | ltr/min | 800 |

| Front Shovel Bucket Capacity SAE 2:1 heaped Crowd Force (ISO) Break-out Force (ISO) | cum kN kN | 16 1.136 1.066 |

| Backhoe Bucket Capacity SAE 1:1 heaped Tear-out Force (ISO) Break-out Force (ISO) | cum kN kN | 15 811 890 |

| Operating Weight (Front Shovel) | t | 250 |

System Components

- Electric System

| System | 24 V |

| Batteries (series/parallel) | 4 x 12 V |

| Alternator | 140 A |

| Standard working lights | 12 LED lights |

| Standard service lights | throughout platform |

| Track adjustment | Automatic hydraulic type |

| Number of shoes | 46 each side |

| Number of top rollers | 3 each side |

| Number of bottom rollers | 7 each side |

| Gradeability | Up to 57% |

| Travel speed (maximum) | 2,4 km/h / 1.5 mph |

| Service brake | Hydraulic brake |

| Parking brake | Wet, multiple-disc |

| Hydraulic motors and drives | 1 |

| Swing brake, service | Hydraulic brake |

| Swing brake, parking | Multiple-disc |

| Swing speed (maximum) | 4,6 rpm |

The high capacity engine radiator is cooled by a mechanically driven fan for superior cooling efficiency and requires little maintenance. The hydraulic system includes large swing-out vertical air-to-oil hydraulic coolers with temperature-regulated hydraulically driven fans.

- Automatic Lubrication

Two hydraulically powered Lincoln single line automatic lubrication systems are provided as standard, complete with time and volume variable controls. The central lube grease system is supplied from a refillable 200 litre (53 gal.) barrel. A second, identical system supplies open gear lubricant to the swing ring teeth through a lube pinion. Replenishment of the barrels is through the service arm.

- Service Capacities

| Hydraulic oil tank | 2.670 ltr | 705 U.S. gal |

| Hydraulic system | 4.400 ltr | 1,160 U.S. gal |

| Fuel | 4.500 ltr | 1,190 U.S. gal |

| Engine coolant | 254 ltr | 67 U.S. gal |

| Engine oil | 190 ltr | 50 U.S. gal |

Drive

Diesel Drive

Tier 2 Engine| Model | Komatsu SDA12V159E-2 Tier 2 certificated |

| Type | 4-cycle, water-cooled, direct injection |

| Aspiration | Turbocharged and aftercooled |

| Number of cylinders | 12 |

| Rated power (SAE J1995) | 940 kW / 1,260 HP @ 1800 rpm |

| Governor | All-speed, electronic |

The integrated engine oil and filter system combining the oil stabilising systems, Reserve and Centinel, with Eliminator oil filter extends the oil change interval to 4.000 hours based on oil analysis.

Electric Drive

| Type | Squirrel-cage induction motor |

| Power output | 900 kW |

| Voltage | 6.000 – 7.200 V* |

| Amperage (approximate) | 96-80 A |

| Frequency (standard) | 50 Hz @ 1500 rpm |

| Optional frequency | 60 Hz @ 1800 rpm |

Hydraulic System

The power train consists of one main drive. Diesel engine or electric motor can be supplied. One gearbox drives three identical main pumps which draw hydraulic oil from an unpressurized hydraulic tank. Open circuit hydraulics provide maximum cooling and filtering efficiency.

| Main hydraulic pumps | 3 x 910 ltr/min | 3 x 240 U.S. gal |

| Relief valve setting | 310 bar | 4,495 psi |

| Swing flow rate | 800 ltr/min | 211 U.S. gal |

| High pressure in line filters one per pump located at the valve block | 200 microns |

Operator Cab

The large and comfortable cab is mounted on 15 viscous damping pads and sound insulated. The cab has automatic climate control and is pressurised. The operator’s seat is air suspended, electrically heated and has a lap seat belt and offers multiple adjustments. The trainer seat is also equipped with a seat belt. Low-effort hydraulic joystick controls are combined with foot controls for front shovel clam, crawler and swing brake. Full instrumentation, KOMTRAX Plus and an AM/FM radio with MP3 ready CD player is fitted. Two windshield wash wipers are synchronised and have two speed and intermittent operation. Two heated rear view mirrors are externally mounted. External metal sun blinds on the cab side windows and internal roller blinds on all windows are standard. There is a left hand sliding window. All windows are tinted parsol green. The cab is equipped with a special penetration proof front window (acc. DIN EN 1063, resistance classification BR2-S) to increase the safety level of the operator. A walkway is mounted in front of cabin.

Major cab engineering standards are:

ISO 10262 Falling Objects Protection Structure

ISO 6394 Noise in operator’s cab is 77 dB(A)

ISO 10263-4 Heating and air conditioning / second heater or air conditioner as option

Operator Cab Standard Equipment

Enclosed steel cab mounted on viscous pads

FOPS structure ISO 10262

Air-conditioning unit Sütrak

Full suspension operator seat with belt

Trainer seat with belt

Controls ergonomic

KOMTRAX Plus (Monitoring System)

Joysticks and controls are hydraulic

2 synchronised windshield wash wipers

AM-FM radio with MP3 ready CD player

External metal sun blinds on side windows

Internal roller blinds on all windows

Impact resistant front window (19mm)

All windows tinted parsol green

Walkway in front of cab

Shovel Attachment

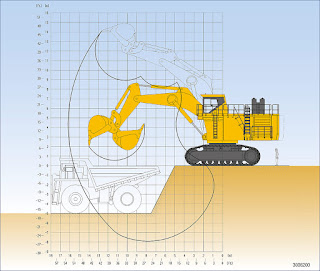

PC 3000 Backhoe

Operating Weights (approx.)

PC 3000 Backhoe:

Operating weight including 8.600 mm / 28'3" boom, 4.000 mm / 13'1" stick, 15 m³ / 19.5 yd³ backhoe bucket, operator, lubricant, coolant, 1/3 filled fuel tank and standard equipment.

Operating weight including 8.600 mm / 28'3" boom, 4.000 mm / 13'1" stick, 15 m³ / 19.5 yd³ backhoe bucket, operator, lubricant, coolant, 1/3 filled fuel tank and standard equipment.

| Shoe Width | Operating Weight | Ground Pressure |

| 800 mm 31" | 252 t 555,700 lb | 23.2 N/cm2 33.6 psi |

| 1.000 mm 39" | 261 t 575,500 lb | 19.2 N/cm2 26.5 psi |

| 1.200 mm 47" | 261 t 575,500 lb | 16.0 N/cm2 23.2 psi |

| Boom length | 8.600 mm | 28'3" |

| Stick length | 4.000 mm | 13'1" |

| Break-out force (ISO) | 890 kN | 200,050 lb |

| Tear-out force (ISO) | 811 kN | 182,290 lb |

| Max. digging height | 14.100 mm | 46'3" |

| Max. dumping height | 9.000 mm | 29'6" |

| Max. digging depth | 7.900 mm | 25'11" |

| Max. digging reach | 16.200 mm | 53'2" |

| Max. digging reach at ground level | 15.600 mm | 51'2" |

| Bucket Capacity (Heaped 1:1) SAE | Width | Teeth | Wear Package acc. abrasiveness | GET System | Max. Material Density (Loose) | |||

| cum | cuyd | mm | foot/inch | qty | t/cum | lb/cuyd | ||

| 12,0 | 15.7 | 3.045 | 9'12" | 5 | heavy |

Hensley XS 252 *

| 2,2 | 3,700 |

| 15,0 | 19.5 | 3.260 | 10'8" | 5 | standard |

Hensley XS 252 *

| 1,8 | 3,000 |

| 16,5 | 21.5 | 3.045 | 9'12" | 5 | standard |

Hensley XS 252 *

| 1,6 | 2,700 |

Alternative buckets on request

PC 3000 Front shovel

Operating Weights (approx.)PC 3000 Front shovel:

Operating weight including 6.000 mm / 19'8" boom, 4.300 mm / 14'1" stick, 16 m³ / 21 yd³ shovel bucket, operator, lubricant, coolant, 1/3 filled tank and standard equipment.

| Shoe Width | Operating Weight | Ground Pressure |

| 800 mm 31" | 250 t 551,300 lb | 22.9 N/cm2 33.2 psi |

| 1.000 mm 39" | 258 t 568,900 lb | 19.0 N/cm2 27.5 psi |

| 1.200 mm 47" | 258 t 568,900 lb | 15.8 N/cm2 22.9 psi |

| Boom length | 6.000 mm | 19'8" |

| Stick length | 4.300 mm | 14'1" |

| Break-out force (ISO) | 1.066 kN | 239,600 lb |

| Crowd force (ISO) | 1.136 kN | 255,340 lb |

| Max. cutting height | 15.100 mm | 49'6" |

| Max. dumping height | 10.200 mm | 33'6" |

| Max. digging depth | 3.300 mm | 10'10" |

| Max. digging reach | 13.300 mm | 43'8" |

| Level crowd at ground level | 4.700 mm | 15'5" |

| Bucket opening width | 2.330 mm | 7'8" |

| Bucket Capacity (Heaped 1:2) SAE | Width | Teeth | Wear Package acc. abrasiveness | GET System | Max. Material Density (Loose) | |||

| cum | cuyd | mm | foot/inch | qty | t/cum | lb/cuyd | ||

| 12,0 | 15.7 | 3.430 | 11'3" | 5 | heavy duty |

Hensley XS 252 *

| 2,4 | 4,000 |

| 16,0 | 21.0 | 3.790 | 12'5" | 6 | standard |

Hensley XS 252 *

| 1,8 | 3,000 |

Alternative buckets on request

Vehicle Health Monitoring System

The KOMTRAX Plus monitoring system is designed for Komatsu mining equipment to provide real time and stored information about the operating status of the machine. Fault messages are immediately available to the operator via a digital display and in the event of critical malfunctions the engine is also shut down. The digital storage provides failure summary and analysis, which can be down loaded by laptop computer. This data will assist in predicting or reduction downtime.

Environment

Refrigerants:

Contains fluorinated greenhouse gas HFC-134a (GWP 1430)

PC 3000-6 D Quantity of gas 3,7 kg, CO² equivalent 5,3 t

PC 3000-6 E Quantity of gas 4,9 kg, CO² equivalent 7,0 t

Vibration levels:

Hand-lever (ISO 5349-1) lower than 2,5m/s²

Whole body vibration and shock (ISO 2631-1) below 0,5m/s²

Harga :

Info Kredit :

Sewa atau Kontrak :

Posting Komentar